Common mistakes to avoid when using ceramic crucibles

Ngày đăng: 11/17/2025 4:28:52 PM - Khác - Toàn Quốc - 44Chi tiết [Mã tin: 6324869] - Cập nhật: 2 phút trước

Ceramic crucibles are indispensable tools in jewelry casting, metal refining, and small-scale smelting, thanks to their durability, heat resistance, and ability to withstand repeated thermal cycles. However, even the best ceramic melting crucible can fail prematurely if used incorrectly. For beginners and experienced metalworkers alike, understanding common mistakes—and how to avoid them—can extend the life of your crucible and improve the overall efficiency of your melting process.

One of the most frequent mistakes is rapid heating or cooling, often called thermal shock. Ceramic materials expand and contract with temperature changes, but they need time to adjust. Placing a room-temperature crucible directly into a high-heat furnace can cause cracking almost instantly. Similarly, removing a hot crucible and setting it onto a cold, metal surface can lead to sudden failure. The solution is simple: preheat the crucible gradually and let it cool on a heat-resistant surface, such as firebrick.

Another issue arises from using the wrong type of crucible for the wrong metal. Not all ceramics behave the same, and some are designed specifically for certain alloys. For example, a crucible suitable for gold or silver may not withstand the higher working temperatures required for metals like brass or bronze. Using a crucible beyond its rated temperature can weaken its structure and introduce impurities into your melt. Always verify compatibility with both the metal type and the operating temperature before starting.

A common but overlooked mistake is overfilling the crucible. Filling it too close to the rim leaves little room for safe pouring and increases the risk of spills. Overflowing molten metal can damage your furnace, tools, or even cause personal injury. A good rule of thumb is to leave at least one centimeter of space from the top to ensure controlled and steady pouring.

Contamination is another critical concern. Some users melt different metals in the same crucible without proper cleaning. Residue from previous melts can react with new metals, affecting purity and color. For example, leftover flux or alloy components can cause unexpected inclusions or discoloration in high-purity gold or silver. To avoid this, clean the crucible thoroughly or dedicate specific crucibles to specific metals.

Finally, many beginners fail to store their ceramic crucibles correctly. Leaving them in damp or dusty environments can weaken their structure over time. Moisture trapped in micro-pores can turn into steam during heating, leading to cracking. Always store crucibles in a dry, clean place and inspect them regularly for hairline fractures.

By recognizing these common mistakes and adopting proper handling habits, you can significantly extend the lifespan of your ceramic crucibles and achieve cleaner, more consistent melting results. Whether you’re a jewelry maker, a hobby caster, or a small-scale metal refiner, mastering these best practices ensures a safer and more efficient workspace.

Tin liên quan cùng chuyên mục Khác

- 0

Chính chủ nhờ bán nhà mỹ đình 76 m giá bán 7.8 tỷ nam từ liêm nhà chủ tự thiết

Cập nhật: vài giây trước - 1

Máy dán băng keo thùng carton tự động wp-5050f giá tốt

Cập nhật: vài giây trước - 0

Cần bán nhà chính chủ phố chính kinh 42 m2 x 5 t 5,2 tỷ ô tô kd

Cập nhật: vài giây trước - 0

Cần bán nhà chính chủ phố mễ trì thượng quận nam từ liêm 45 m2 x 5 t nhỉnh 7 tỷ

Cập nhật: vài giây trước - 0

Chính chủ cần bán mảnh đất phố đỗ đức duc quận nam từ liêm 30 m2 mt rộng 3,9tỷ

Cập nhật: vài giây trước  2

2Chính chủ bán căn hộ blue star – view ubnd & công viên gia lâm, giá 4.47 tỷ -

Cập nhật: 1 phút trước 2

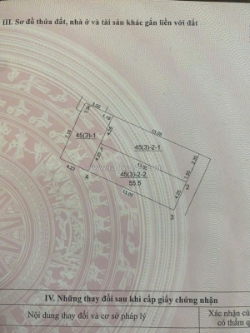

2Chính chủ cần bán 55.5 m2 đất ngô xuân quảng - gia lâm, giá 10.55 tỷ, lh

Cập nhật: 2 phút trước- 0

Tủ bếp inox cánh composite chữ l – inox trung thành

Cập nhật: 3 phút trước - 0

Công dụng của thuốc trừ sâu radiant - thethuangroup.com

Cập nhật: 3 phút trước - 0

Cực hiếm chính chủ cần bán nhà phố trần quốc toản quận hoàn kiếm 87m2 x4 t

Cập nhật: 4 phút trước - 0

Cần bán mảnh đát chính chủ đường láng hòa lạc 65 m2 giá nhỉnh 1 tỷ ô tô 4 làn

Cập nhật: 5 phút trước - 1

Máy đóng gói hút chân không thực phầm giá rẻ

Cập nhật: 5 phút trước - 0

Chính chủ cần bán nhà vị trí cực hiếm nhà phố cự lộc thanh xuân 35m2 x5 t 7,38

Cập nhật: 5 phút trước  2

2Lưỡi dao lạng da cá castle xuất xứ đức giá tốt

Cập nhật: 5 phút trước 1

1Đến hạn trả nợ tôi chính chủ cần bán lô đất hàng xóm đô thị xanh vi

Cập nhật: 6 phút trước- 0

Cần bán mảnh đát chính chủ đường láng hòa lạc 65 m2 giá nhỉnh 1 tỷ ô tô 4 làn

Cập nhật: 6 phút trước  2

2Chỉ 1,4 tỷ sở hữu nhà 1 trệt 1 lửng – sổ riêng – ở ngay

Cập nhật: 6 phút trước- 0

Cần bán nhàchính chủ quận nam từ liêm phố mỹ đình 52 m2 x 5 t 6.8 tỷ ô tô kd

Cập nhật: 7 phút trước - 0

Chính chủ cần bán biệt thự hàm nghi mỹ đình 190 m2 x 5 t mt rộng 10m 44 tỷ ô tô

Cập nhật: 7 phút trước - 0

Chính chủ cần bán tòa nhà ccmn phố đồng bát quận nam từ liên 90 m2 x 9 t nhỉnh

Cập nhật: 7 phút trước - 0

Chính chủ cần bán chân đế chung cư trần hữu dực 110 m t1 giá nhỉnh 12 tỷ

Cập nhật: 7 phút trước - 0

Chính chủ cần bán tòa nhà ccmn phố đồng bát quận nam từ liên 90 m2 x 9 t nhỉnh

Cập nhật: 7 phút trước  2

2♥ lô góc k thông gần mt trần cao vân + lê độ, 67m2, mê lửng cứng sạch đẹp

Cập nhật: 8 phút trước 2

2Cho thuê phòng – 09 đường phương canh - xuân phương - nam từ liêm

Cập nhật: 8 phút trước- 0

Cần bán nhà chính chủ phố nguyễn đổng chi quân nam từ liêm 46 m2 x 6 t mt rộng

Cập nhật: 8 phút trước  2

2Bán mp vương thừa vũ 75mx 5t - kinh doanh - tương lai mở rộng đường giá trị

Cập nhật: 10 phút trước- 0

Chính chủ cần bán nhà phố chùa hà quận cầu giấy 43 m2 x 5 t mt rộng nhỉnh 8 tỷ

Cập nhật: 10 phút trước - 0

Cách sử dụng thuốc trừ sâu radiant - thethuangroup.com

Cập nhật: 11 phút trước - 0

Cần bán lô đất chính chủ cực hiếm phố lê quang đạo quận nam từ liêm 80 m2 nhỉnh

Cập nhật: 11 phút trước - 0

Cần bán mảnh đát chính chủ đường láng hòa lạc 65 m2 giá nhỉnh 1 tỷ ô tô 4 làn

Cập nhật: 11 phút trước - 0

Máy đóng đai tự động dba-200 giá tốt nhất

Cập nhật: 11 phút trước - 1

Máy đóng gói hút chân không hai buồng hút giá rẻ

Cập nhật: 11 phút trước - 1

Máy quấn màng pe kiện hàng, kiện hành lý

Cập nhật: 12 phút trước - 1

Máy hàn miệng túi bán tự động ps-450 giá rất rẻ

Cập nhật: 12 phút trước - 0

Chính chủ cần bán mảnh đất quận nam từ liêm phường phương canh hiếm hót 55m2

Cập nhật: 12 phút trước - 1

Máy đai niềng thùng chaly jn-740

Cập nhật: 12 phút trước - 0

Chính chủ cần bán nhà phố mỹ đình quận nam từ liêm 39 m2 x 6 tmt rộng nhỉnh 4

Cập nhật: 13 phút trước - 1

Máy hàn miệng túi đạp chân giá siêu rẻ

Cập nhật: 13 phút trước - 0

Máy dán băng keo góc thùng carton giá tốt miền nam

Cập nhật: 13 phút trước - 0

Cần bán lô đất chính chủ cực hiếm phố lê quang đạo quận nam từ liêm 80 m2 nhỉnh

Cập nhật: 14 phút trước - 0

Chính chủ cần bán nhà phố phú mỹ 60 m2 x 5 tầng nhỉnh 10 tỷ có ô chờ thang máy

Cập nhật: 14 phút trước - 0

Cần bán nhàchính chủ quận nam từ liêm phố mỹ đình 52 m2 x 5 t 6.8 tỷ ô tô kd

Cập nhật: 15 phút trước - 0

Chính chủ cần bán nhà đường lê văn lương khuất duy tiến 36m2 x5 t nhỉnh 3 tỷ ô

Cập nhật: 15 phút trước  2

2Hàng hiếm cửa đại hội an mặt tiền 17m dòng tiền 35tr/tháng chỉ 10,2 tỷ

Cập nhật: 16 phút trước- 0

Thi công nhà bungalow homestay đẹp, thu hút du khách

Cập nhật: 16 phút trước  1

1Những điểm cộng đáng giá của chiếc điều hòa giấu trần daikin

Cập nhật: 17 phút trước- 0

Chính chủ cần bán nhà phố phú diễn quận bắc từ liêm 33m2 x 4 tầng nhỉnh 4 tỷ ô

Cập nhật: 17 phút trước - 0

Chính chủ cần bán nhà phố ngọc trục đại mỗ quận nam từ liêm 35 m2 x 5 t nhỉnh

Cập nhật: 17 phút trước - 0

Chính chủ cần bán nhà quận nam từ liêm bán nhà phương canh 32 m2 x 5 t nhỉnh 3

Cập nhật: 17 phút trước - 1

Dụng cụ bấm kim thùng carton bằng tay

Cập nhật: 17 phút trước